Breathing Easy: How Asbestos Air Testing Safeguards Public Health in the UK

Asbestos fibres, when released into the air, can be inhaled and cause serious health issues

Introduction to asbestos air testing

Asbestos is a dangerous mineral that was widely used in construction materials until its ban in the UK in 1999. However, many buildings still contain asbestos, posing a significant risk to public health. Asbestos fibres, when released into the air, can be inhaled and cause serious health issues, including lung cancer and mesothelioma. That's why asbestos air testing plays a crucial role in safeguarding public health in the UK.

The importance of asbestos air testing for public health

Asbestos air testing is a vital process that helps identify the presence of asbestos fibres in the air and determines whether the levels are within safe limits. By conducting regular air testing, potential asbestos exposure can be identified and mitigated, reducing the risk of asbestos-related diseases. The primary goal of asbestos air testing is to protect the health and safety of individuals in their homes, workplaces, and public buildings.

Different types of asbestos air testing - Reassurance, Background, Clearance, Leakage, Personal

There are various types of asbestos air testing, each serving a specific purpose in assessing asbestos exposure.

- Reassurance Air Testing & Monitoring: This type of testing is conducted to provide reassurance that the levels of asbestos fibres in the air are below the control limit. It is often performed after the accidental disturbance of Asbestos Containing Materials (ACM's) to ensure that the area is safe for occupation.

- Background Air Testing & Monitoring: Background testing is carried out in areas where asbestos-containing materials (ACMs) are known to be present but are not being disturbed. It helps establish the baseline levels of asbestos fibres in the air for comparison with future test results.

- Clearance Air Testing & Monitoring: Clearance testing is essential after asbestos removal or remediation works. It confirms that the area is free from asbestos fibres and safe for reoccupation. The clearance indicator of 0.01 f/ml is used as a benchmark to determine whether the area meets the required standards.

- Leakage Air Testing & Monitoring: Leakage testing is performed during asbestos removal or remediation to ensure that no asbestos fibres are escaping into surrounding areas. It helps ensure the prevention of the spread of asbestos contamination during the works.

- Personal Air Testing & Monitoring: Personal air testing involves monitoring the exposure of individuals who are at risk of asbestos exposure due to their job or specific circumstances. This type of testing ensures that workers are not being exposed to harmful levels of asbestos fibres beyond the protection factor of their Respiratory Protective Equipment (RPE) and that the control measures being employed to reduce airborne fibre levels are working effectively.

Understanding the Control Limit of 0.1 f/ml and Clearance Indicator of 0.01 f/ml

In asbestos air testing, specific control limits and clearance indicators are used to assess the safety of an area. The Control Limit of 0.1 f/ml refers to the maximum acceptable concentration of asbestos fibres in the air. If the levels exceed this limit, immediate action is required to mitigate the risk. On the other hand, the Clearance Indicator of 0.01 f/ml is used during clearance testing to determine whether an area is safe for reoccupation. If the levels are below this indicator, the area is considered asbestos-free and can be safely used.

The process of asbestos air testing - sampling, analysis, and reporting

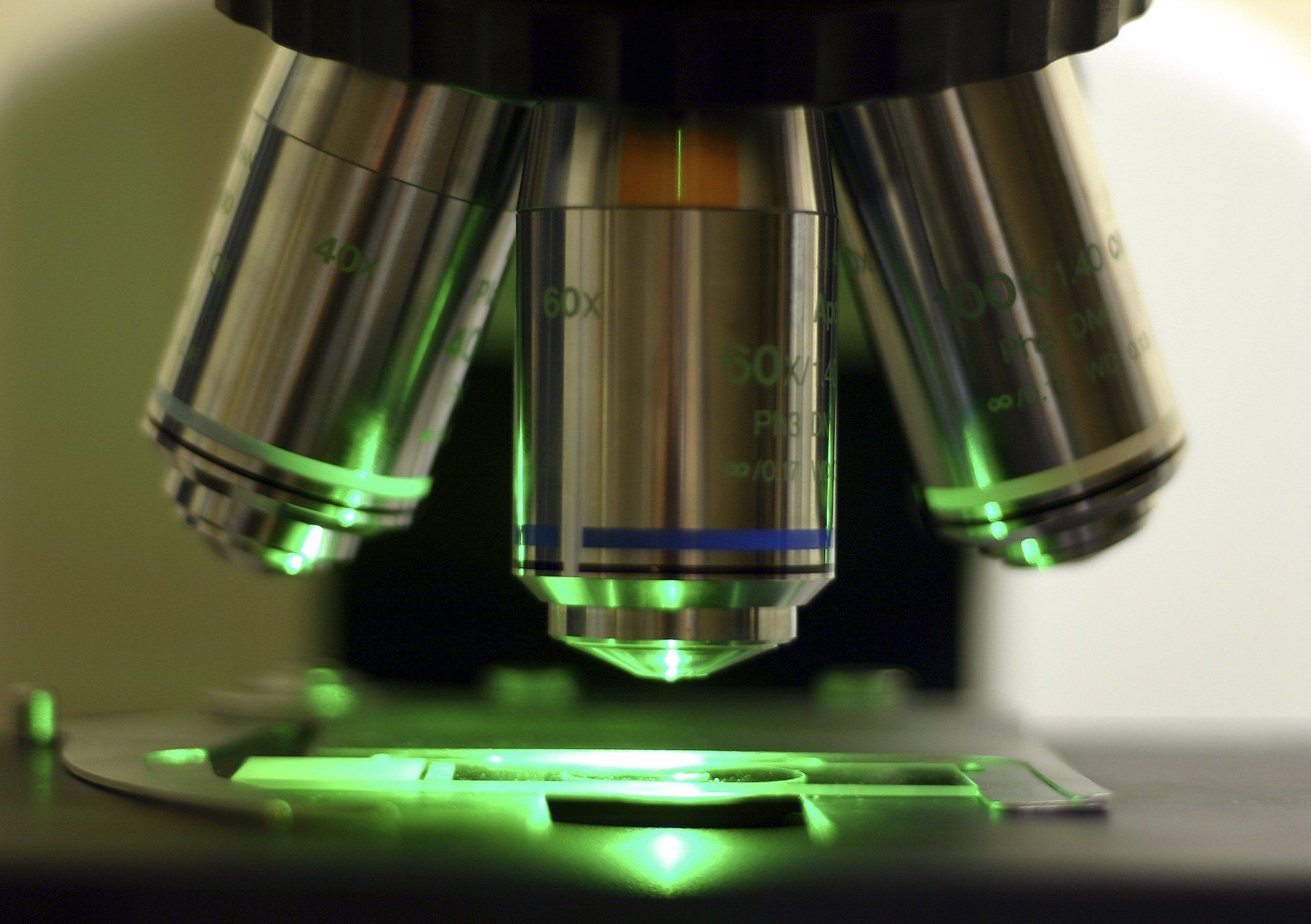

Asbestos air testing involves several steps, starting with sampling the air to collect airborne particles. These samples are then analysed using polarised light microscopy (PLM) techniques to identify and quantify asbestos fibres. The process includes fibre counting, where a trained analyst counts the number of fibres found in the sample. This information is then used to determine the concentration of asbestos fibres in the air.

Once the analysis is complete, a comprehensive report is generated, detailing the findings and the concentration levels. This report serves as a valuable tool for property owners, employers, and individuals to understand the risk of asbestos exposure and take appropriate measures to protect themselves and others.

The role of microscopy and fibre counting in asbestos air testing

Polarised Light Microscopy (PLM) plays a crucial role in asbestos air testing as it allows for the identification and quantification of asbestos fibres. Through microscopy, analysts can distinguish between asbestos and non-asbestos fibres, ensuring accurate results. Fibre counting, carried out by trained analysts, provides valuable information about the concentration of asbestos fibres in the air, helping determine whether the levels are within safe limits.

Understanding key terms - LQL, Control Limit, Clearance Indicator

To fully comprehend asbestos air testing, it is essential to understand key terms such as LQL (Lower Quantification Limit), Control Limit, and Clearance Indicator.

The LQL, refers to the lowest concentration of asbestos fibres that can be reliably detected and quantified in a sample. Where insufficient quantities of air have been sampled, the accuracy of the air test is significantly reduced meaning it isn't possible to guarantee fibre levels below this limit.

The Control Limit of 0.1 f/ml is the maximum acceptable concentration of asbestos fibres in the air, beyond which immediate action is required to reduce the risk of further exposure and to reduce the fibre levels in the area. This will usually involve investigation by a professional company such as Consulo Compliance followed by remediation works by a licensed asbestos removal contractor.

The Clearance Indicator of 0.01 f/ml is used during clearance testing to determine whether an area is safe for reoccupation. Fibre levels above this limit will require further investigation to identify the source of the fibre followed by further removal work and fine cleaning by the licensed contractor.

The role of the RICE Scheme in asbestos air testing

The RICE (Respiratory Inorganic Fibres Counting and Evaluation) Scheme is a vital component of asbestos air testing. It provides a standardized framework for the analysis and evaluation of asbestos fibres in air samples. Laboratories participating in the RICE Scheme undergo rigorous testing and quality control measures to ensure accurate and reliable results.

Benefits of regular asbestos air testing

Regular asbestos air testing offers numerous benefits in safeguarding public health. By conducting periodic testing, potential asbestos exposure can be identified early, allowing for timely remediation measures. This proactive approach helps reduce the risk of asbestos-related diseases and ensures the safety of individuals in their homes, workplaces, and public buildings. Regular testing also provides peace of mind, knowing that the air is free from harmful asbestos fibres.

Common misconceptions about asbestos air testing

Despite the importance of asbestos air testing, there are some common misconceptions that need to be addressed. One misconception is that asbestos air testing is unnecessary if asbestos-containing materials are intact. However, even undisturbed ACMs can release fibres into the air over time, posing a risk to occupants. Another misconception is that asbestos air testing is a complex and costly process. In reality, with advancements in technology and the availability of accredited laboratories, asbestos air testing has become more accessible and affordable than ever before.

Conclusion: The significance of asbestos air testing in safeguarding public health in the UK

Asbestos air testing plays a critical role in safeguarding public health in the UK. By identifying and quantifying asbestos fibres in the air, potential exposure can be mitigated, reducing the risk of asbestos-related diseases. The different types of asbestos air testing, including reassurance, background, clearance, leakage, and personal testing, each serve specific purposes in assessing asbestos exposure. Understanding key terms like LQL, Control Limit of 0.1 f/ml, and Clearance Indicator of 0.01 f/ml is essential for interpreting asbestos air testing results accurately. Regular testing and the role of the RICE Scheme further contribute to the effectiveness of asbestos air testing in protecting individuals and ensuring safe environments.

Contact Consulo Compliance today to check you're not being exposed to asbestos fibre in your home or workplace.